A team of researchers at the universities of Linköping in Sweden and Okayama in Japan have developed a combination of materials that can morph into shapes and harden. The team was inspired by the growth of bones in the skeleton.

The unique material starts out soft before hardening through a bone development process that uses the same materials found in the skeleton.

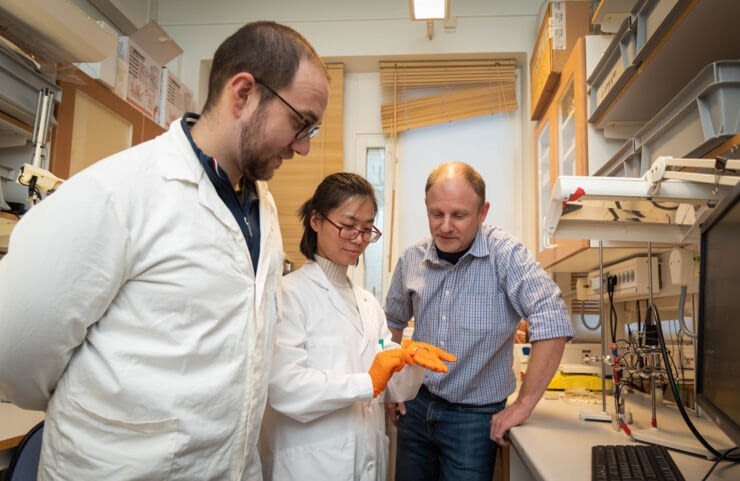

Edwin Jager is an associate professor at the Department of Physics, Chemistry and Biology (IFM) at Linköping University.

“We want to use this for applications where materials need to have different properties at different points in time. Firstly, the material is soft and flexible, and it is then locked into place when it hardens. This material could be used in, for example, complicated bone fractures. It could also be used in microrobots — these soft microrobots could be injected into the body through a thin syringe, and then they would unfold and develop their own rigid bones,” says Jager.

Discovering Unique Biomolecule

The team came up with the idea during a research visit in Japan where Jager met with Hiroshi Kamioka and Emilio Hara, who conduct research into bones. The researchers discovered a type of biomolecule that could stimulate bone growth in a short period of time, and they wondered if it could be combined with materials research to develop new materials.

The study was published in Advanced Materials.

In the study, the team created a simple “microrobot” that can take different shapes and change stiffness. They relied on alginate, which is a gel material where a polymer material is grown on one side. Alginate is also electroactive and changes its volume when a low voltage is applied, and this causes the microrobot to bend in a specific direction.

The researchers then attached biomolecules on the other side of the gel. The biomolecules allow the soft gel material to harden, and they are extracted from the cell membrane of a type of cell crucial to bone development. The material can then be immersed in a cell culture medium, which is an environment that contains calcium and phosphor and resembles the body. Once it is immersed, the biomolecules make the gel mineralise and harden.

Potential Applications

There are many potential applications for this new material, such as bone healing. When It is in its soft form, the material could move into spaces in complicated bone fractures before expanding. After hardening, it would form the foundation for the construction of new bone.

The researchers deployed the material in their study, wrapping it around chicken bones. The artificial bone was then developed and grew together with the chicken bones.

The researchers can also determine how the microbot will bend by making patterns in the gel. For example, if they make perpendicular lines on the surface of the material, the microrobot will bend in a semicircle. If they make diagonal lines, it will bend like a corkscrew.

“By controlling how the material turns, we can make the microrobot move in different ways, and also affect how the material unfurls in broken bones. We can embed these movements into the material’s structure, making complex programmes for steering these robots unnecessary,” says Jager.

The researchers will now look further into the properties of the materials and how they work together with living cells. This could provide deeper insight into the biocompatibility of the materials.

Credit: Source link