Europe is worried about weaning itself off Russian gas and oil. But sanctions on trade with Russia could result in another crisis as well — a lack of fertiliser.

Russia and Belarus are major producers of fertilisers and as much as 25% of Europe’s supply of key ingredients comes from Russia. And with the backlash to its invasion of Ukraine, the Kremlin’s trade and industry ministry recommended earlier this month that the country’s fertiliser producers temporarily halt all exports.

A cut to the supply of fertilisers will hike up costs and increase the risk of crop failure in Europe, raising the possibility of food prices rocketing.

“Europe must find ways to endure this and greatly reduce its dependence on Russia; in the current situation, it is clear how important it is to be able to build a capacity for self-sufficiency,” says Gustaf Forsberg, CEO and founder of Swedish fertiliser startup Nitrocapt.

Fertilisers are most commonly made up of three parts — Nitrogen (N), Phosphorus (P) and Potassium (K) in varying amounts depending on the crop. Nitrogen in particular is manufactured by using large quantities of oil and gas.

In recent years, a number of startups have come up with ways to try to solve this issue.

What if we can actually use livestock manure?

Livestock manure is a very traditional way of fertilising fields — but what if you could supercharge the process and make this natural product as effective as chemical fertilisers?

Norwegian startup N2 Applied has been researching that for the last ten years. It has developed a machine that uses electricity to extract nitrogen oxide from the air and pump it into livestock slurry (that’s liquid manure to you and me). Increasing the amount of nitrogen in the slurry prevents ammonia and methane from leaking out and creates a better and less smelly fertiliser than untreated slurry.

“In this case, the farmer is recycling nutrients on the farm and becomes independent of external nitrogen inputs in the form of chemical fertiliser. And because it is a circular model, you can produce food with a much lower environmental footprint,” N2 Applied’s CEO Carl Hansen tells Sifted.

N2 Applied has nine pilot installations on commercial farms across Scandinavia, the Netherlands and the UK. With the feedback from those projects, N2 Applied is developing a new generation machine which will come to the market later this year.

Pee for victory

Other startups in the field have more novel solutions. Toopi, a French fertiliser startup founded in 2019, use human urine to make its fertiliser. Gardening magazines have long gushed about the benefits of pee for fertilising plants, but no one has made a business out of collecting it for commercial use — until now.

According to Michael Roes, the founder of Toopi, urine is naturally rich in NPK and micronutrients. In addition to its use as a fertiliser it’s excellent at helping microorganisms grow in the soil.

“In France alone, we produce 30bn litres of urine and we cannot make use of that much. Instead, we collect urine from urinals placed in large buildings and in places like sports arenas,” says Roes.

Toopi is at an early stage but has already signed an agreement with a big fertiliser distributor for all its produce in the next three years. In that time the company will construct the territorial transformation units needed for the venues where the urine is collected.

For Roes, urine is key for the future of fertilisers. “The only way to stop using or use less mineral fertilisers, is to recycle urine. You don’t have any trace of chemicals,” he says.

Cutting out carbon

There are also ways of producing NPK fertilisers without large amounts of gas and oil. Traditional nitrogen fertilisers are responsible for 2.5% of global fossil-related greenhouse gas emissions, but a number of startups are working on ways to make them with a much smaller carbon footprint.

One of them is NitroCapt, a Swedish startup that’s setting up a pilot factory in Germany next year to produce nitrogen fertilisers without any greenhouse gas emissions. This is produced by fixation of nitrogen from the air by using its energy-efficient patented reactor that can operate from renewable intermittent electricity off-grid.

“Our goal is to be able to contribute with a technology that will be able to create local self-sufficiency in nitrogen, which is the most important plant and nutrient in terms of volume and cost,” Forsberg says.

“Due to the current development, we are reviewing how we can further accelerate our development in order to get out and offer our technology as soon as possible.”

Another Swedish company working on a new solution is Cinis Fertilizer, which recently signed an agreement with battery producer Northvolt to use the sodium sulphate salt byproduct from its manufacturing to create potassium sulphate. By using industrial byproducts and a technique using lower temperatures it will have a 75% lower carbon footprint than traditional fertilisers.

“With the rise in costs of gas and oil the last year, we have seen the interest for sustainable fertiliser production located in Europe,” CEO Jacob Liedberg tells Sifted.

“What we are doing isn’t new, but how the traditional fertiliser companies have done it in the past has been by heating up sulphuric acid and sodium chloride to 700 degrees, which you need a lot of oil and gas to do. We use waste products from manufacturing and can get the same end product using low temperatures and renewable energy.”

Cinis Fertilizer will sell its products to fertiliser companies to be a component of what farmers eventually buy. NitroCapt is looking to make local companies become producers that can supply the farmers directly.

Stimulants on top of NPK

If NPK fertiliser is a farmer’s bread and butter, stimulants like minerals are the jam on top. Some of these minerals can also be found in batteries.

Zinc, manganese and copper are metals that are beneficial for crops and the Finnish startup Tracegrow has found a way to extract and purify the metals from used alkaline batteries and turn them into organic foliar (applied directly to a plant’s leaves) fertiliser.

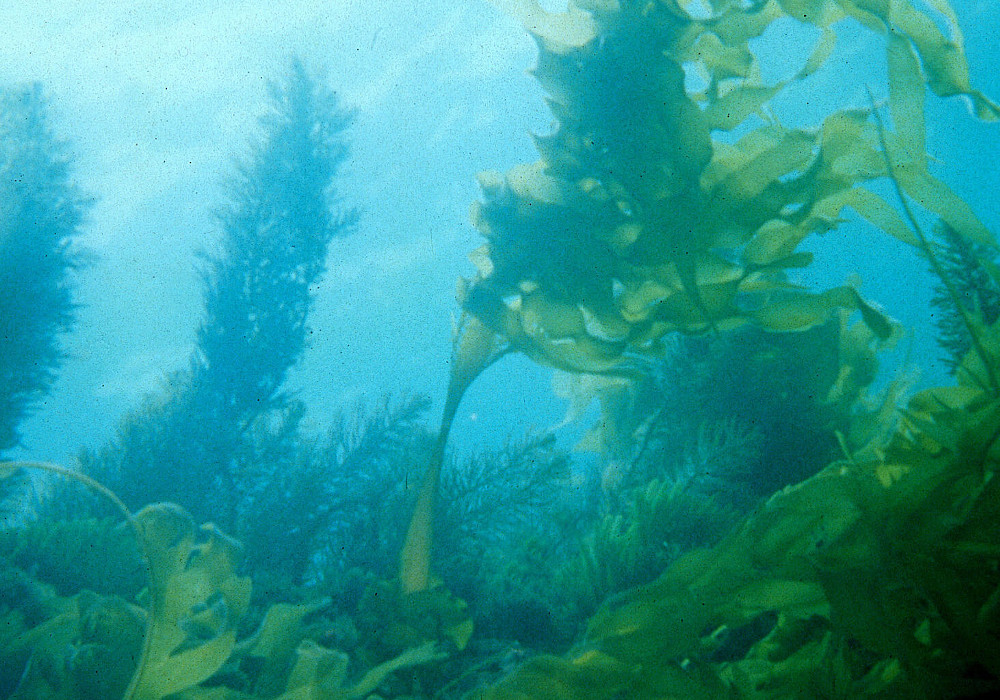

Similarly, seaweed has plenty of beneficial micronutrients, like the minerals found in batteries, as well as alginates (quick sugar to plants) and phytohormones (good for crop development). This “ancient” fertiliser is something that the Spanish startup Ficosterra is already selling to its customers across Europe, as well as in Mexico and Israel.

While Tracegrow and Ficosterra produce can’t replace NPK fertiliser, Luis Lombana, founder and CEO of Ficosterra, says using these stimulants can reduce the amount of expensive NPK needed to produce the same crop yield.

“We are now conducting a project which is financed by the United Nations Development Programme in which we are proving that you can reduce the conventional fertilisation by 30% and when complemented with other products, you’re getting the same yield as you did before,” Lombana says.

Solutions to the looming fertiliser crisis are needed urgently. The European Union imported 7.2m tonnes of fertiliser in 2020. With the decline in the supply of Russian gas, which is used at European fertiliser factories, the situation is very strained, according to Forsberg.

Ukraine, popularly known as “Europe’s granary”, has put a stop to all fertiliser exports and is likely to have limited capacity to produce cereals for Europe for the foreseeable future. This is likely to further increase grain prices above the already high level. The risk for reduced food production and increasing prices are likely.

The newly developed fertiliser methods are unlikely to be able to stop this from happening. But in the long term, they may be able to make Europe more self-sufficient and also cut the greenhouse gas emissions that traditional fertilisers have long been responsible for.

Mimi Billing is Sifted’s Nordic correspondent and tweets from @MimiBilling

Credit: Source link