MBDA, a leading European manufacturer in the aerospace and armaments sector, wanted to robotize certain processes in small series or even single unit production by allowing an operator with no programming skills to teach the robotic system in just a few seconds, the process to be carried out and then to execute the cycle with complete confidence without human supervision.

Fuzzy Logic’s Repplix application software module addresses all aspects of this requirement in a cost-effective manner. The first use case selected was the tedious, manual cleaning of the molds used to manufacture composites.

MBDA France’s Bourges site produces numerous small series of composite parts that have to be molded. Each mold is manually stripped clean before being used in production. The parts to be treated are diverse and numerous.

In each series, the level of residue to be stripped off and its location may vary. This method of operation requires protecting the operator from exposure to toxic substances.

“At MBDA we look for agility when it comes to robotization,” Head of the Factory of the Future Project at MBDA Vincent Rafin said. “We want to robotize tasks which cause muscolo-skeletal disorders in our operators and which occur in certain cases in the production of very small series or even single parts, so we need to keep the non-recurring costs of programming as low as possible. Programming a robot to define the trajectories of a laser is not the right approach for small series production, it is time-consuming and costly and has to be done by a roboticist.

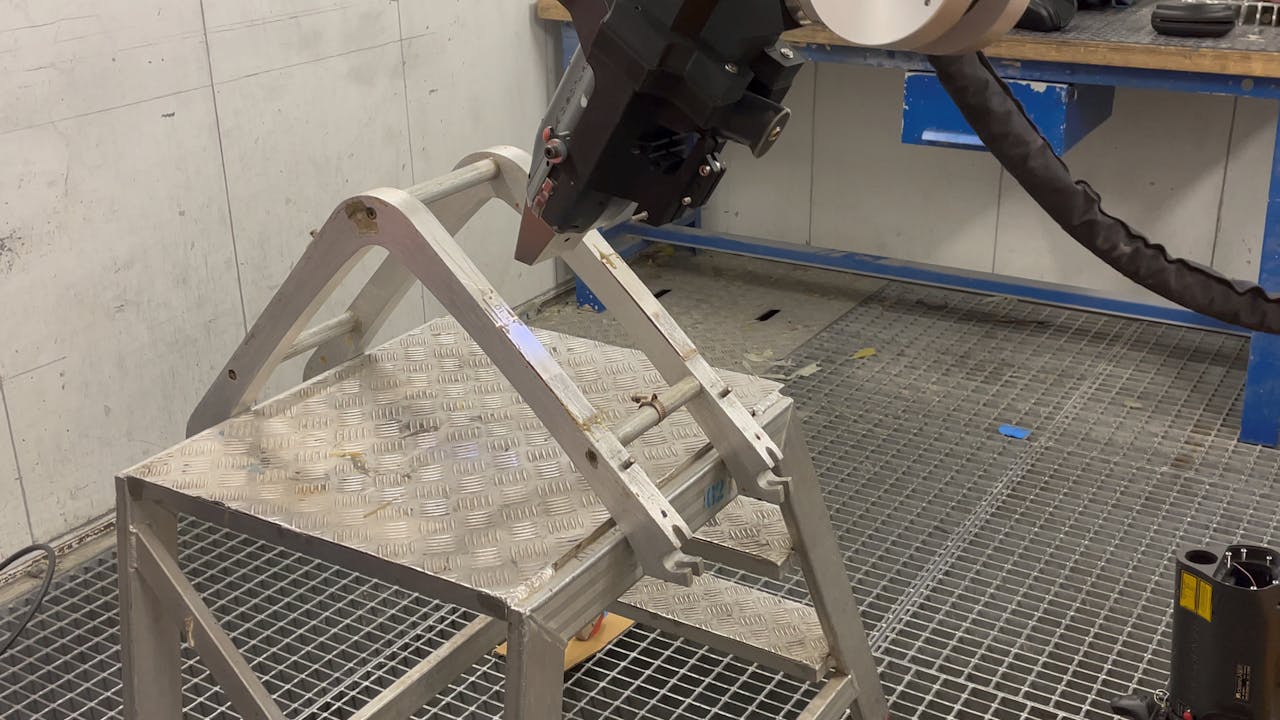

Programming a Laser Stripper on the Fly, With a Non-Roboticist Operator

Fuzzy Logic developed Repplix, an extension of its Fuzzy Studio software, in cooperation with MBDA. A portable learning device, controlled by the operator using his knowledge of the application task, teaches the Repplix software the first laser alignment.

A monitoring function, performed via a real-time digital twin of the robotic installation created in Fuzzy Studio, takes into account collision monitoring and trajectory feasibility in the robot´s environment.

Alert parameters are set up and trajectory capture combines several process parameters such as laser triggering and power. The operator, who is not a roboticist, is also able to modify the trajectory and process parameters via the graphical interface and can do so even after the learning phase.

From this digital twin, the cycle is launched and the robot moves with the laser, guided by the accurate capture of the trajectory learned from the operator. The speed at which the robot operates is set directly in the software. It can differ from the speed in the learning phase.

The cycle is performed autonomously by the robot without the need for operator supervision. The same process, which takes only a few minutes, is done for each new series of molds.

Repplix is Uniquely Suited to Robotizing Industrial Processes Like These

The solution developed in this way is executed with millimeter precision and is capable of extension to even more demanding applications in the future. The manual operation can be reproduced with ease because the learning device is the representation of the real tool and is not directly linked to the robot. The operator manages the execution and planning of the movement himself using the software and the parametrized alerts.

The time needed to program the mold cleaning operation is slashed from several hours to only a few minutes. Productivity is increased by automating the cleaning operation and the risks for the operator are reduced. This makes robotizing this operation profitable, both in terms of HSE and economics.

Jean-Michel Duchazeaubeneix, CEO of Meliad, details how Repplix opens up new perspectives for laser stripping applications.

“We offer robotic laser stripping solutions, but this robotization remains complicated because it has to be done by specialists,” Duchazeaubeneix said. “Repplix offers us the possibility of rapidly and easily deploying our laser solutions across a wide range of repair or maintenance applications which have been difficult to implement until now, whether they be the aeronautics industry or nuclear or defense. “

“This innovation is the achievement the vision of MBDA engineers and operators who, working in close collaboration with innovative SMEs, have succeeded in taking the first step towards implementing a robotic solution which breaks the cost barrier for a wide range of use cases thanks to programming by non-invasive capture of the operators’ know-how,” MBDA’s Director of Innovation and Future Technologies Denis Gardin said.

Credit: Source link