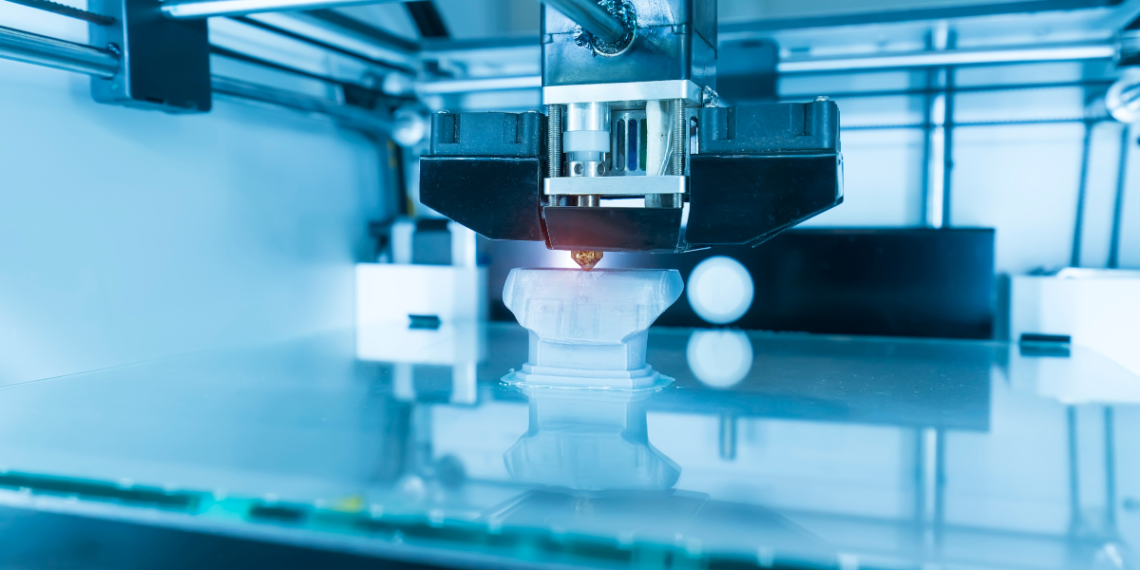

In a groundbreaking development at the forefront of biotech, researchers at ETH Zurich have achieved a monumental leap with the successful printing of a robotic hand boasting bones, ligaments, and tendons using a state-of-the-art laser scanning technique. This revolutionary technology, in collaboration with a US start-up, not only pushes the boundaries of soft robotics but also holds immense promise for the future of biotechnology and medicine.

Revolutionizing 3D Printing in Biotech

The conventional limitations of 3D printing in the realm of biotechnology are being shattered by the innovative integration of 3D printing with a laser scanner and a feedback mechanism. This breakthrough enables the creation of intricate, durable robots from a spectrum of high-quality materials in a single printing process. This not only extends the scope of soft robotics but also paves the way for unprecedented applications in the medical field.

Slow-Curing Polymers: A Biotech Game-Changer

The key to this biotech revolution lies in the utilization of slow-curing polymers, specifically thiolene polymers. These polymers, with superior elastic properties and a rapid return to their original state after bending, outperform the traditional fast-curing polyacrylates used in 3D printing. This newfound capability opens up exciting possibilities for creating intricate biological structures that mimic the flexibility and resilience of natural tissues.

Biotech Applications: Printing Bones, Ligaments, and Tendons

The successful printing of a robotic hand with bones, ligaments, and tendons using slow-curing polymers marks a watershed moment for biotech applications. This innovative approach allows for the precise replication of biological structures, introducing a level of complexity and functionality previously unattainable. The implications for biotech and medicine are profound, with the potential to revolutionize prosthetics, tissue engineering, and personalized medicine.

Advantages of Slow-Curing Polymers in Medicine

In the context of medicine, the advantages of slow-curing polymers become even more apparent. Thiolene polymers, with their excellent elastic properties, offer a promising avenue for developing medical devices and implants that closely mimic the mechanical properties of human tissues. This could significantly enhance the performance and integration of implants within the human body, reducing the risk of rejection and improving patient outcomes.

Soft Robotics in Medicine: Redefining Human-Robot Collaboration

The soft nature of robots, exemplified by the newly printed robotic hand, holds immense potential in the medical field. Soft robots pose a lower risk of injury when interacting with humans, making them ideal for tasks involving patient care and rehabilitation. The integration of soft robotics into medicine could usher in a new era of human-robot collaboration, where these adaptable machines seamlessly assist in medical procedures and rehabilitation exercises.

Future Implications for Biotech and Medicine

As the boundaries of 3D printing in biotech continue to be pushed, the future implications for medicine are vast. The ability to print intricate biological structures opens avenues for creating custom implants tailored to individual patient needs. This could revolutionize the field of orthopedics, allowing for the creation of implants that closely match the patient’s anatomy, thereby improving the success rates of surgeries and reducing recovery times.

Bioprinting: A Glimpse into the Future of Medicine

The successful integration of 3D printing with slow-curing polymers also sets the stage for advancements in bioprinting. The ability to print complex biological structures with varying degrees of stiffness and elasticity brings us closer to the reality of printing functional organs for transplantation. While this vision is still in the realm of the future, the recent breakthrough signifies a critical step forward in the journey toward bioprinting.

Incorporating Innovation into the Medical Industry

For the medical industry, incorporating this groundbreaking innovation involves reimagining the landscape of medical device manufacturing and prosthetics. The precision offered by slow-curing polymers opens new possibilities for creating implants that seamlessly integrate with the human body. Collaborations between researchers, medical professionals, and industry leaders are essential to harness the full potential of this technology.

Collaborative Research and Development

The medical industry can actively engage in collaborative research and development initiatives to explore the diverse applications of slow-curing polymers in medicine. This involves bringing together experts in materials science, robotics, and medical professionals to collectively innovate and develop new solutions. Cross-disciplinary collaborations could lead to the creation of advanced medical devices, prosthetics, and implants that significantly improve patient outcomes.

Regulatory Considerations and Ethical Guidelines

As with any groundbreaking technology in medicine, regulatory considerations and ethical guidelines play a crucial role. The medical industry must work closely with regulatory bodies to establish standards for the use of 3D printing with slow-curing polymers in medical applications. Addressing ethical considerations, such as patient consent and data security, ensures the responsible and ethical deployment of these innovations in the medical field.

Educational Initiatives for Healthcare Professionals

Incorporating this innovation into the medical industry also requires educational initiatives for healthcare professionals. Training programs and workshops can familiarize medical professionals with the capabilities and potential applications of 3D printing with slow-curing polymers. This knowledge transfer ensures that healthcare professionals are well-equipped to leverage these technologies for the benefit of their patients.

Industry-Driven Transformation: Shaping the Future of Medicine

This transformative innovation in 3D printing with slow-curing polymers signals a paradigm shift in the medical industry. Industry leaders have the opportunity to drive this transformation by investing in research, development, and the integration of these technologies into medical practices. By actively participating in shaping the future of medicine, companies can position themselves at the forefront of innovation and contribute to the advancement of patient care.

Conclusion: A New Frontier for Biotech and Medicine

In conclusion, the successful printing of a robotic hand with bones, ligaments, and tendons using slow-curing polymers marks a pivotal moment in biotech and medicine. This innovation transcends the boundaries of traditional 3D printing, offering a glimpse into a future where customized implants, bioprinted organs, and advanced medical devices are a reality. The collaborative efforts of researchers, industry leaders, and healthcare professionals will be instrumental in unlocking the full potential of this technology and shaping the future of biotech and medicine.