Water pipes are one of the most unsung inventions that have shaped human civilization for thousands of years. They have allowed waste to be carried from cities, supplied fresh water to its inhabitants, and drained water after heavy rains to prevent flooding. The importance of all of these benefits can’t be emphasized enough – large populations wouldn’t be able to be supported without water pipes coursing throughout the cities.

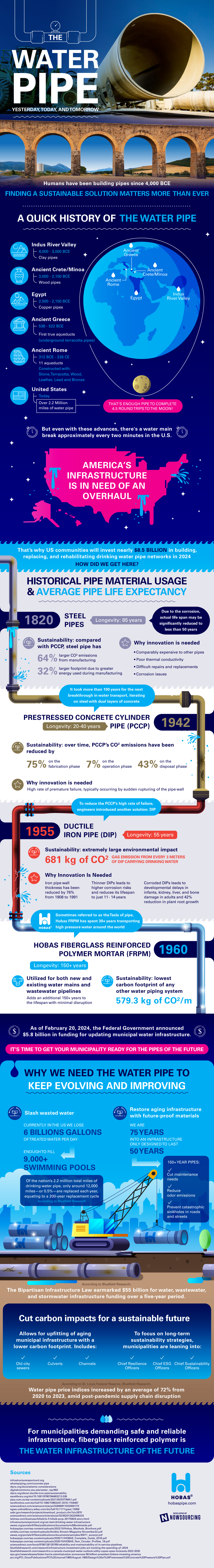

They have been in use since 4000 BCE, with the first iterations being made of clay in the Indus River Valley. The Mediterranean soon became a hotspot for more variations of this invention, including wood pipes in Ancient Crete/Minoa in 3000 – 2150 BCE and copper pipes in Egypt in 2500 – 2150 BCE. Ancient Greece was the birthplace of the first true aqueducts, which were made of underground terracotta pipes. Ancient Rome expanded upon this invention by constructing 11 new aqueducts with materials such as stone, terracotta, wood, leather, lead, and bronze.

Fast forward thousands of years, the United States has greatly expanded on these inventions. There are now over 2.2 million miles of water pipe throughout the country, which is enough pipe to complete 4.5 trips to the moon and back. Despite the incredible amount of infrastructure allowing Americans to sustain themselves, there are still a lot of problems with the current system. In fact, every two minutes there is a water main break, which can waste lots of usable water. In order to resolve this issue, there will need to be a major overhaul of the current system. US communities are very aware of this need, and are investing $8.5 billion in building, replacing, and rehabilitating drinking water pipe networks in 2024.

In order to understand the necessity of this overhaul, it is important to understand the history behind these pipes and the current problems each widely used pipe material presents. The first modern steel pipes appeared in 1820, which had a relatively short lifespan of 85 years. Due to corrosion, this lifespan can be reduced to less than 50 years, which can drive up replacement costs and overall expenses compared to other pipes. It also has poor thermal conductivity, which can terrify those who hate cold showers. To top it off, steel pipes do not perform well in the sustainability category. Compared to PCCP, steel pipes have 64% larger carbon dioxide emissions from manufacturing and a 32% larger footprint due to greater energy used during manufacturing.

Steel pipes were used for over 100 years, until 1942, when the next breakthrough in water transportation occurred. This came in the form of prestressed concrete cylinder pipe (PCCP), which is steel dual layered with concrete. It has a significantly shorter life span, with only 20-40 years. Since its conception, the sustainability of PCCP has been greatly improved, especially related to carbon dioxide emissions. These emissions have been reduced by 75% on the fabrication phase, 7% on the operation phase, and 43% on the disposal phase. Lots of innovation is needed for these types of pipes because they have a high rate of premature failure, especially when there is a sudden rupturing of the pipe wall.

PCCP has a notoriously high rate of failure, so engineers sought out another solution. They settled on ductile iron pipe (DIP), which has a longevity of 55 years. While it lasts longer than PCCP, it presents a huge host of problems. For one, it releases a huge amount of carbon dioxide, which can create a very large environmental impact. Its thickness reduces drastically over time as well, which reduces its lifespan to just 11-14 years. On top of its need for frequent replacements, corroded DIPs can cause detrimental health problems for people exposed to this corruption. These problems can include developmental delays for babies, along with kidney, liver, and bone damage in adults.

Finally, after many years of problems arising from these suboptimal piping materials, scientists finally created the Hobas fiberglass reinforced polymer mortar (FRPM) in 1960. These pipes are able to last for over 150 years and have the lowest carbon footprint of any other water piping system. These pipes are a great choice for the piping methods that will be used for the rehauling of the current system. With the use of Hobas FRPM, maintenance needs will be cut thanks to longer lifespans, odor emissions will be reduced, and catastrophic sinkholes in roads can be successfully prevented. The Federal government is already on board, pledging $5.8 billion in funding for updating this essential infrastructure.