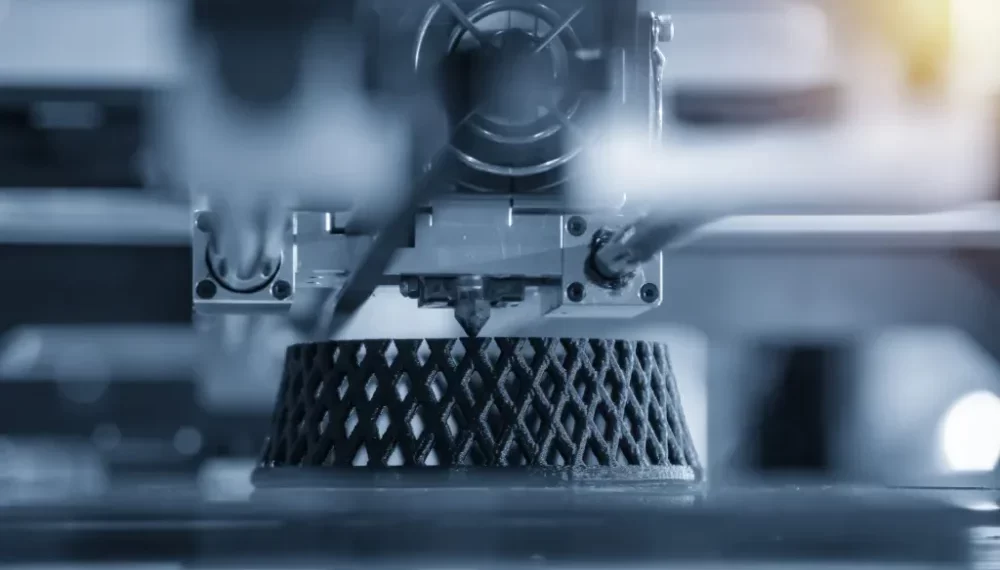

Additive manufacturing, also known as 3D printing, has come a long way since its inception in the 1980s. Today, it is considered a game-changer for the space industry and holds immense potential for transforming society. This article delves into the ways additive manufacturing is revolutionizing the space industry and its broader implications on society.

Space Industry Applications

Cost Reduction and Efficiency

One of the most significant advantages of additive manufacturing is the potential to reduce costs associated with space missions. Traditional manufacturing methods often require intricate and labor-intensive processes, which are both time-consuming and expensive. With 3D printing, however, components can be created with minimal waste and fewer resources, leading to increased efficiency and cost savings.

In-Space Manufacturing

In-space manufacturing, facilitated by additive manufacturing, is an emerging area with the potential to revolutionize space missions. With the ability to print spare parts and other components in space, the need for launching large quantities of spare parts from Earth is minimized. This reduces the overall mass of payloads, cutting launch costs and enabling missions to be more flexible and adaptive.

Novel Materials and Designs

Additive manufacturing enables the use of new materials and innovative designs that were previously impossible or impractical with traditional methods. For example, lightweight and strong materials, such as metal alloys and composites, can be combined to create optimized structures for space applications. Furthermore, the freedom to create intricate geometries allows engineers to develop more efficient and functional spacecraft components.

Societal Impacts

Environmental Sustainability

Additive manufacturing can contribute significantly to environmental sustainability. The reduction of material waste, the ability to recycle materials, and the potential to utilize resources from space (e.g., Moon or asteroid mining) can help minimize the ecological footprint of manufacturing processes.

Democratization of Space

As the cost of space exploration decreases due to additive manufacturing, more countries and private entities can participate in space missions. This democratization of space can help foster international collaboration and contribute to scientific advancements.

Stimulating Economic Growth

The growing adoption of additive manufacturing in the space industry is expected to stimulate economic growth by creating new jobs, driving innovation, and attracting investments. The rise of new industries, such as space tourism, is also anticipated to generate significant economic benefits.

Education and Workforce Development

The use of additive manufacturing in space applications can help educate and train the next generation of engineers, scientists, and technicians. As the technology becomes more accessible and affordable, educational institutions can incorporate hands-on learning experiences, encouraging students to develop skills in design, engineering, and manufacturing.

Everyday Citizens’ Impact

The impact of additive manufacturing on the space industry has far-reaching consequences that extend to everyday citizens. As 3D printing continues to reshape the way we approach space exploration, several aspects of daily life can be affected by these advancements.

Credit: Source link